HALO® – A Better Path to Separations

Technology Overview

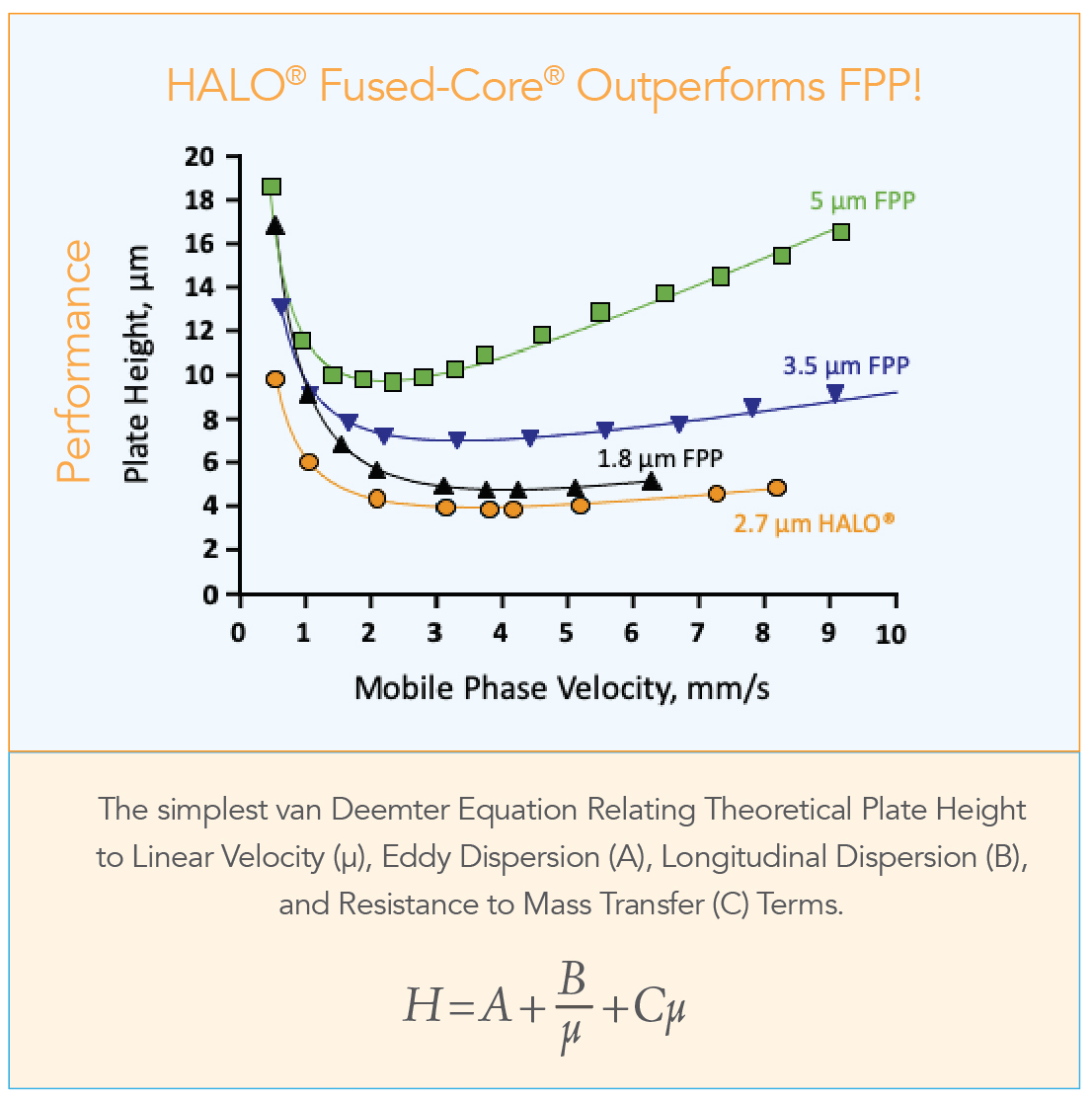

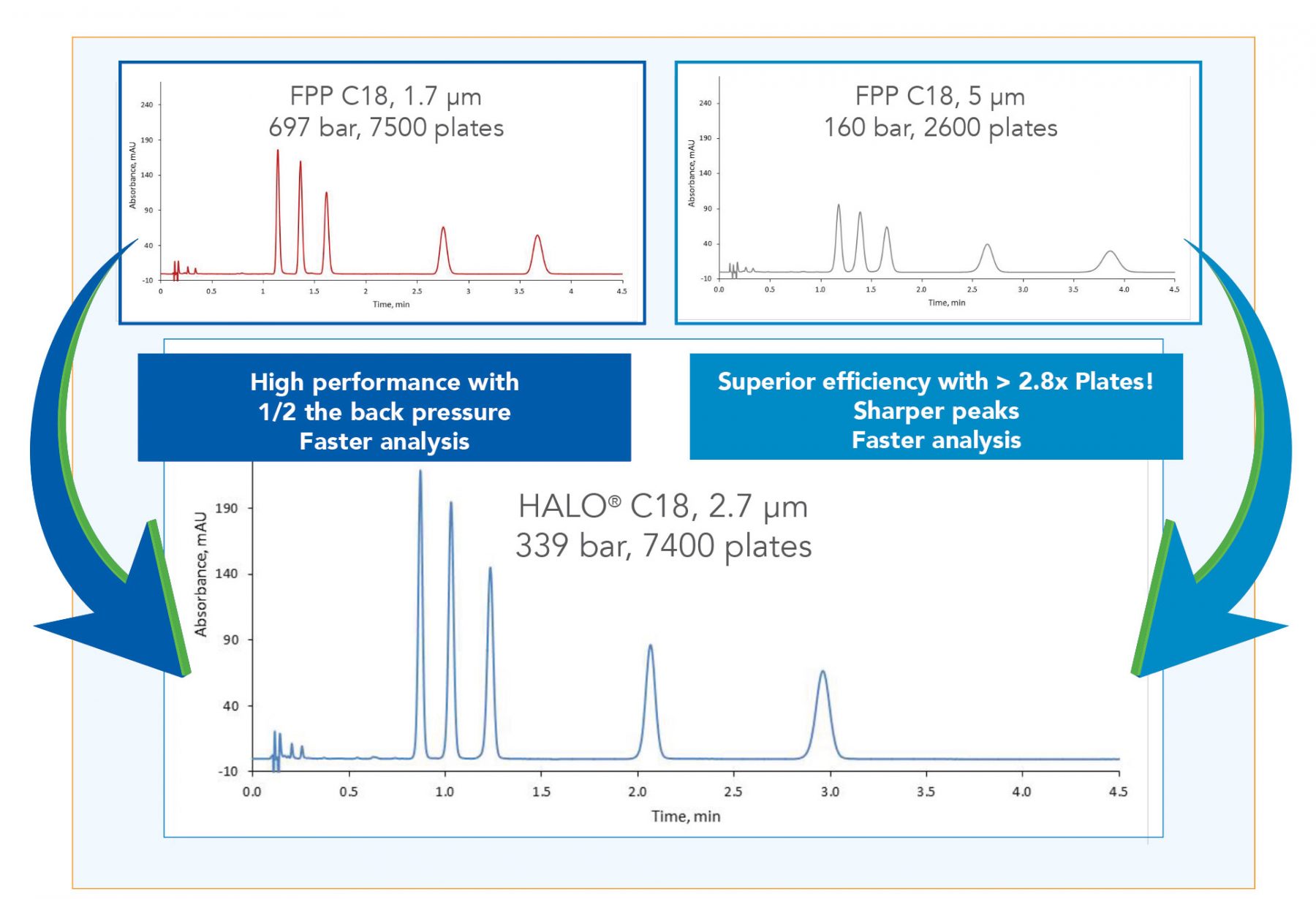

The original HALO® Fused-Core® columns are able to perform competitively versus sub-2 µm fully porous columns and substantially outperform 3 and 5 µm fully porous columns delivering the goal of increased performance without the consequence of high back pressures!

As separation demands evolve so does Advanced Materials Technology’s industry leading innovation.

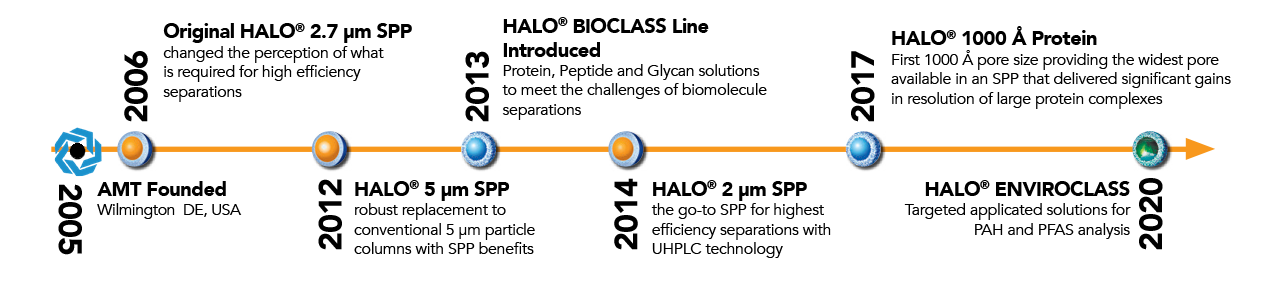

What began in 2006 at AMT with the 2.7 µm C18 HALO® particle that proved the possibility for high efficiency separations with conventional HPLC’s has revolutionized the chromatography world! The innovation continues by forging a new path through manipulations of the particle morphology which has advanced the chromatographic separations in the biopharmaceutical and environmental industries. The timeline above represents AMT’s commitment to delivering innovative tools to enhance the separation resolution afforded by the column technology.

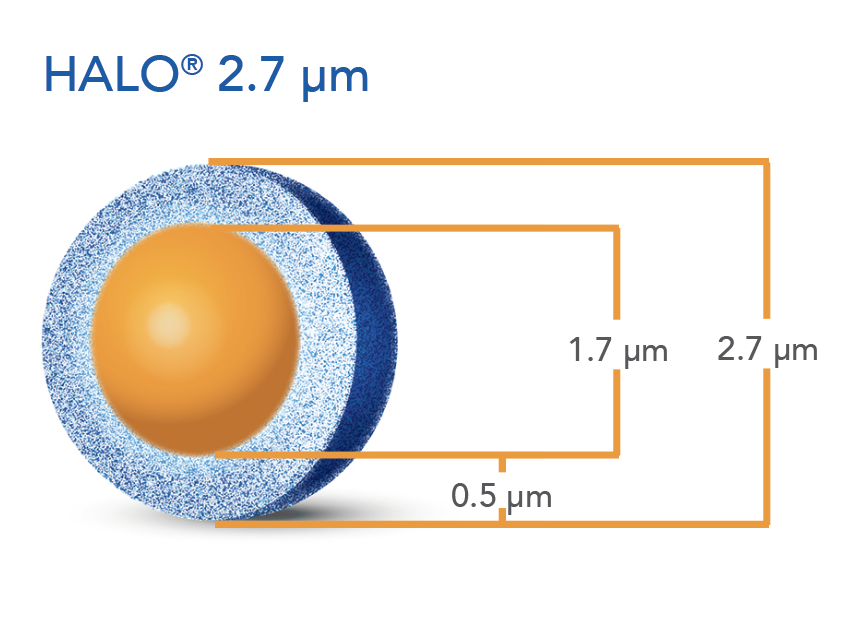

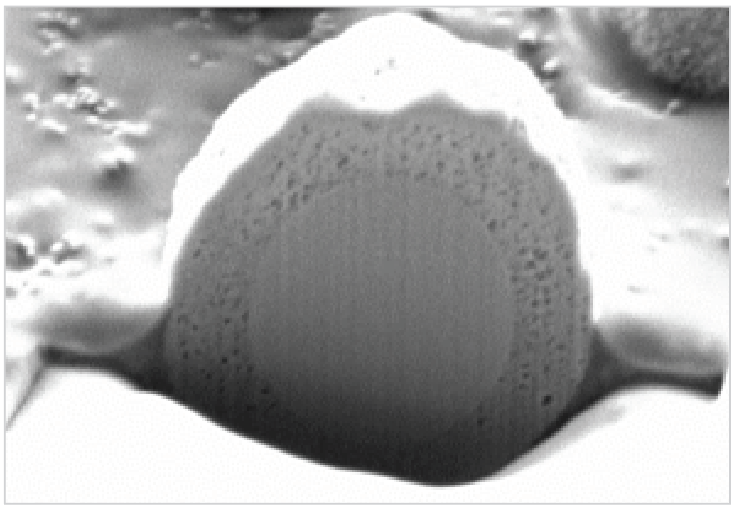

FIB – SEM image of first commercial HALO® particle with 2.7 µm total size consisting of a 1.7 µm solid silica core and a 0.5 µm shell.

How HALO® Columns Deliver Higher Efficiency

Higher efficiencies (higher plate count (N), smaller plate height, (H)) for SPP columns are due to a combination of all three van Deemter A, B and C terms being smaller for SPP particles.

- Reduction in eddy diffusion (40% smaller van Deemter “A term”) due to more uniform analyte flow paths through the column bed

- Much lower longitudinal broadening (25–30% smaller van Deemter “B term”) due to the presence of the solid core inside the particles

- Flatter van Deemter plot and higher optimum linear velocity (μopt, ∝flow rate, “C term”) due to the shorter diffusion distances into the particles

The original HALO® Fused-Core® columns are able to perform competitively versus sub-2 µm fully porous columns and substantially outperform 3 and 5 µm fully porous columns delivering the goal of increased performance without the consequence of high back pressures!

Practically Speaking

Ready to Discover More?

Download our 6 step guide METHOD CONVERSION GUIDEBOOK to convert your methods today!

why we do it

The challenge of improving the presentation of the sample to the detector is our focus. As the realization of SPP benefits became more mainstream, recognized at first by thought leaders and then more universally adopted, ongoing development of the particle morphology has been underway.

company profile

Advanced Materials Technology, founded in 2005, has been focused on one mission – Improving the presentation of the sample to the detector. Using our novel Fused-Core® particle design, we have challenged conventional wisdom and engineered innovative solutions for the separations community.

All company operations and functions are proudly located in Wilmington, Delaware, USA with world-wide distribution and accessibility.

AMT invites a company culture of diversity, respect and pride in delivering quality products. We embrace ISO 9001 standards in our work systems and daily work. We pledge to have a dynamic leadership team which promotes our culture of excellence embedded in every employee.

taking advantage of the vast hplc applications of fused-core® technology

Visit our solutions pages to learn more about the best uses and benefits of Fused-Core® Technology.

Small Molecule Solutions

From an ultra-fast separation of a few compounds to a more complex natural product sample containing hundreds of analytes, HALO® columns offer an optimized solution for separation challenges.

Biopharmaceuticals are inherently more complex than small molecules. HALO® BioClass columns have been specifically designed to accomplish these bio-separation goals with a simplified and more effective solution.

Solutions for other persistent, high environmental-impact contamination agents such as pesticides, mycotoxins, herbicides, and more all based upon HALO’s 15 years of innovative and trusted technology.