ADVANCED MATERIALS TECHNOLOGY

QUALITY FOCUSED, CUSTOMER DRIVEN

- ISO 9001 Certified

- Customer-focused processes and procedures

- Stage Gate process for Development Cycle

- Engineering for Long-Term Reliability and Performance

- Continuous improvement throughout our 20-year history

Structured Development

Our Stage Gate process ensures customer requirements are met from concept to completion.

Rigorous Testing

Each stage requires specific quality tests before advancing from R&D to Engineering to Manufacturing.

Consistent Quality

Our standardized process ensures collaboration and robust decision-making regardless of product complexity.

MAKING OF A HALO® PARTICLE

AMT has revolutionized chromatographic separations with the Fused-Core® particle technology.

Unlike competitors who utilize intermediates in their production, we control the entire manufacturing process from starting raw materials through finished columns.

With over 200+ quality checks throughout production, HALO® HPLC columns deliver industry-leading consistency, and high chromatographic efficiencies without the backpressure consequence.

Join us on the journey of engineering HALO® columns…

STARTING WITH

QUALITY RAW MATERIALS

We begin with three high purity raw materials, add energy and engineering to create the HALO® Fused-Core® particle

Core Creation

The foundation of the Fused-Core® particle

HALO® particles are silica based and begin with a spherical core.

The core is responsible for the reduction in diffusion path which leads to more analyte to bonded phase interactions creating high efficiencies.

![]()

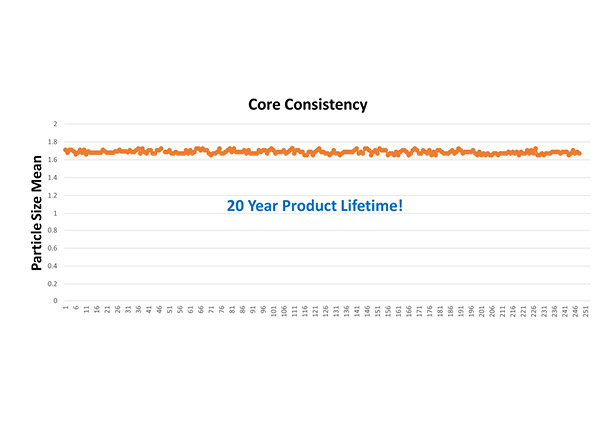

20 Years of measuring Mean Particle Size:

RSD of < 0.08%

Quality

Testing

Tests

Coating

Building the Shell

Silica nanoparticles (1/10,000th thickness of a human hair!) are coated onto the core to create the shell.

AMT’s precise process ensures batch to batch consistency in pore size and shell thickness. This results in tight, industry-leading, particle size distributions.

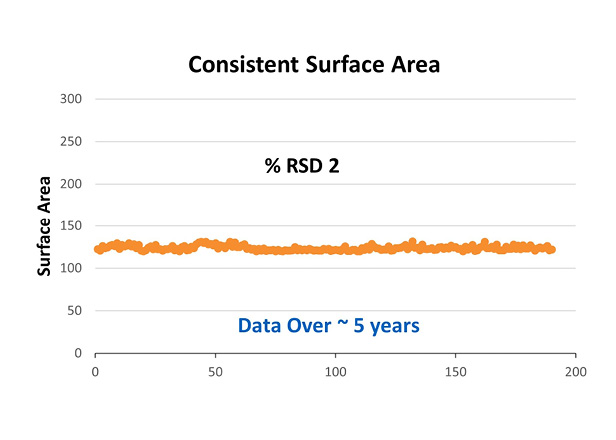

Surface Area

Highly reproducible retention resulting from excellent control of surface area.

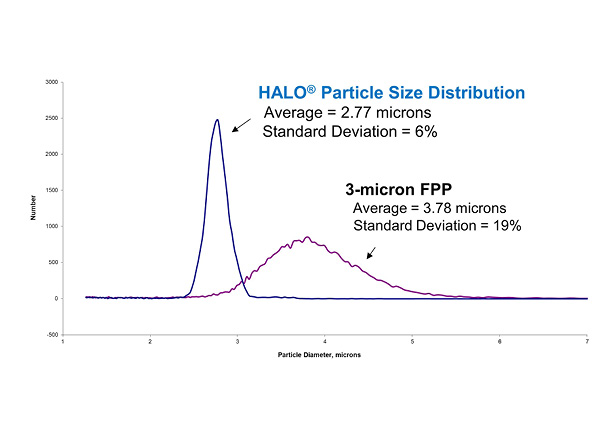

Particle Size Distribution

The narrow particle size distributions from the tightly controlled coating process allow for highly stable column beds.

Quality

Testing

14+

23+

55+

47+

94+

100+

in-process controls

1

2

3

4

5

6

7

QC/QA

Tests

Finishing

SURFACE OPTIMIZATION

AMT uses a proprietary method to create uniform and consistent surface silanols. The particle is now ready for bonding or use.

AMT uses a challenging test at neutral pH with a basic analyte to confirm the uniformity of the surface silanols.

Bonding

Adding Chemistry

The silica particle is now perfectly sized and ready to be functionalized.

Temperature, humidity, and reaction times are precisely controlled as we functionalize the surface with different ligands such as C18 or Biphenyl.

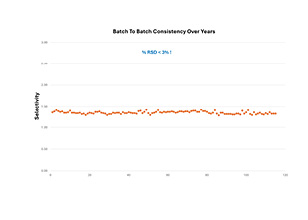

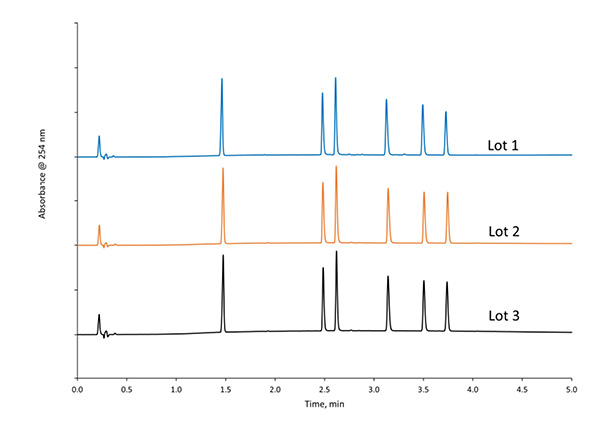

Every bonded batch undergoes rigorous QA testing under multiple conditions to verify retention, selectivity, and peak shape to ensure the results achieved today will be reliable tomorrow and years from now.

Quality

Testing

Performance-based application testing performed on every batch

Lot to Lot reproducibility is a critical factor in quality. Typical result of % RSD over multiple bondingsis < 0.3%!

Column Loading

Final Assembly

The journey culminates as our perfectly sized, chemically optimized Fused-Core® particles are packed into stainless steel tubes under precisely controlled high pressure.

Our automated process ensures consistent density and eliminates variation in packing quality.

Optimized frit porosities and end fittings are applied where the finished column moves on to final QC testing.

Quality

Testing

09

12

18

20

in-process controls

1

2

3

4

5

6

QC/QA

Tests

Testing and Packaging

Quality in Delivery

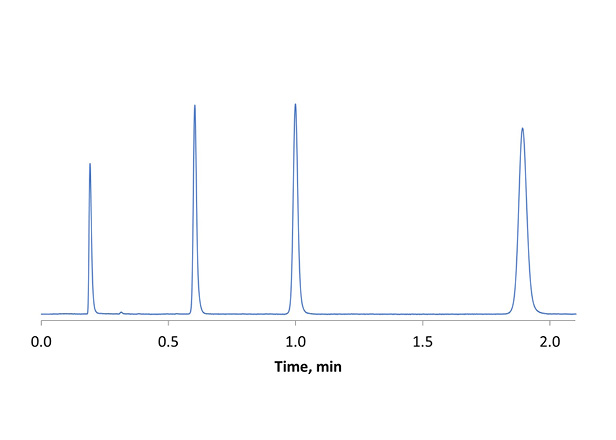

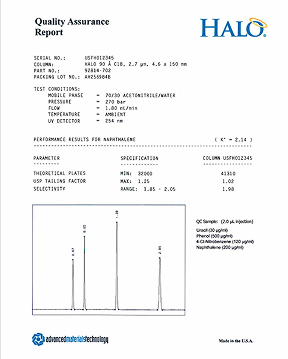

Before any HALO® column leaves our facility, it undergoes comprehensive performance testing. Every AMT column ships with its own test chromatogram, verifying it meets our exacting standards.

This isn’t just quality control—it’s our brand promise.

Beyond Manufacturing Excellence

Fast Shipping & Continued Support

Our commitment to quality extends beyond manufacturing:

- 99% on-time delivery worldwide for over a decade

- 24 hour order processing on analytical columns

- Each column includes a quality verification chromatogram

and care and use sheet - Recyclable, environmentally-friendly packaging

- Dedicated technical support from experienced scientists