AUTHOR: Conner McHale, Technical Support Specialist, Advanced Materials Technology INTRODUCTION to PFAS ANALYTICAL METHODS Per-…

Improving Small Molecule Analysis: Increasing the Sensitivity While Reducing Solvent Consumption by Using 1.5 mm ID Columns

AUTHOR:

Stephanie Schuster, Ph.D., Senior Technical Support Scientist

ABSTRACT

The new HALO® 1.5 mm ID columns offer an alternative to analytical and narrow bore columns for greater separation performance with the benefits of increased sensitivity, reduced solvent consumption/reduced waste disposal costs, and ease of implementation with standard UHPLC systems compared to larger ID (2.1 mm and greater) and smaller ID (1 mm and less) columns. Examples will be shown to demonstrate the benefits of this novel column dimension which is used for superficially porous particles for the first time.

INTRODUCTION

Chromatographers are familiar with the benefits of reducing column ID: increased sensitivity, reduced solvent consumption therefore reduced waste disposal costs/overhead expenses, and reduced sample consumption. However, there are challenges that must be overcome to realize these benefits, including the need for specialized pumps that are capable of accurately delivering reduced flows. With the new HALO® 1.5 mm ID columns, existing UHPLC systems with low dispersion can be used instead of having to purchase specialized HPLC systems. The HALO® 1.5 mm ID columns offer increased sensitivity compared to larger ID columns (2.1 mm ID and greater). These columns also offer solvent savings since they are run at approximately half the flow rate of 2.1 mm ID columns, which means solvent savings of 50%. Finally, the HALO® 1.5 mm column hardware is robust and rugged, similar to analytical bore columns which enable long column lifetimes.

One aspect of switching to smaller ID columns is the impact of extracolumn dispersion(1-4), which is the broadening or spreading of an analyte band outside of the column. When too much extracolumn dispersion is present, the true performance of the column becomes masked causing reduced resolution and intensity (broad, short peaks). In order to successfully implement the HALO® 1.5 mm ID columns with UHPLC systems, the extracolumn dispersion should be minimized by using shorter, smaller ID connecting tubing, reduced injection volumes, and smaller volume flow cells for UV detection. All of these changes must be balanced in order to be able to operate at reasonable flow rates without overpressurizing the system and with the desired sensitivity.

KEYWORDS: sensitivity, solvent savings, HALO 90 Å C18, microflow, extracolumn dispersion, 1.5 mm

EXPERIMENTAL:

The examples in this report will demonstrate increased sensitivity and reduced solvent use for a homologous series of alkylphenones, a mix of over-the-counter cough and cold medicines, and cannabinoid standards. All of the experiments were run using a Shimadzu Nexera (Columbia, MD) that had been optimized with an IDEX MarvelXACT™ PEEK-lined stainless steel connector (Northbrook, IL) from the injector to the column of 75 µm x 350 mm. The low dispersion flow cell was used in place of the semi-micro flow cell. All solvents used were MS grade. Acetonitrile, mobile phase additives, and individual standards were obtained from MilliporeSigma (St. Louis, MO).

Alkylphenones:

Column: HALO 90 Å C18, 2.7 µm, 1.5 x 100 mm

Part Number: 9281X-602

Column: HALO 90 Å C18, 2.7 µm, 2.1 x 100 mm

Part Number: 92812-602

Mobile Phase A: Water; B: Acetonitrile

Isocratic: 50/50 A/B

Flow Rate: 0.2 mL/min (1.5 mm); 0.39 mL/min (2.1 mm)

Back Pressure: 236 bar (1.5 mm); 310 bar (2.1 mm)

Temperature: 35 °C

Detection: UV 280 nm, PDA

Injection Volume: 0.5 µL

Sample Solvent: 84/16 water/methanol

Cough and Cold Medicines:

Column: HALO 90 Å C18, 2.7 µm, 1.5 x 150 mm

Part Number: 9281X-702

Column: HALO 90 Å C18, 2.7 µm, 2.1 x 150 mm

Part Number: 92812-702

Mobile Phase A: Water/0.15% TFA; B: Acetonitrile/0.1% TFA

Gradient: 5-50 %B in 8 min

Flow Rate: 0.2 mL/min (1.5 mm); 0.4 mL/min (2.1 mm)

Back Pressure: 425 bar (1.5 mm); 470 bar (2.1 mm)

Temperature: 35 °C

Detection: UV 280 nm, PDA

Injection Volume: 0.5 µL

Sample Solvent: 84/16 water/methanol

Cannabinoids:

Column: HALO 90 Å C18, 2.7 µm, 1.5 x 150 mm

Part Number: 9281X-702

Column: HALO 90 Å C18, 2.7 µm, 4.6 x 150 mm

Part Number: 92814-702

Mobile Phase A: Water/0.1% Formic Acid; B: Acetonitrile/0.1% Formic Acid

Isocratic: 75 %B

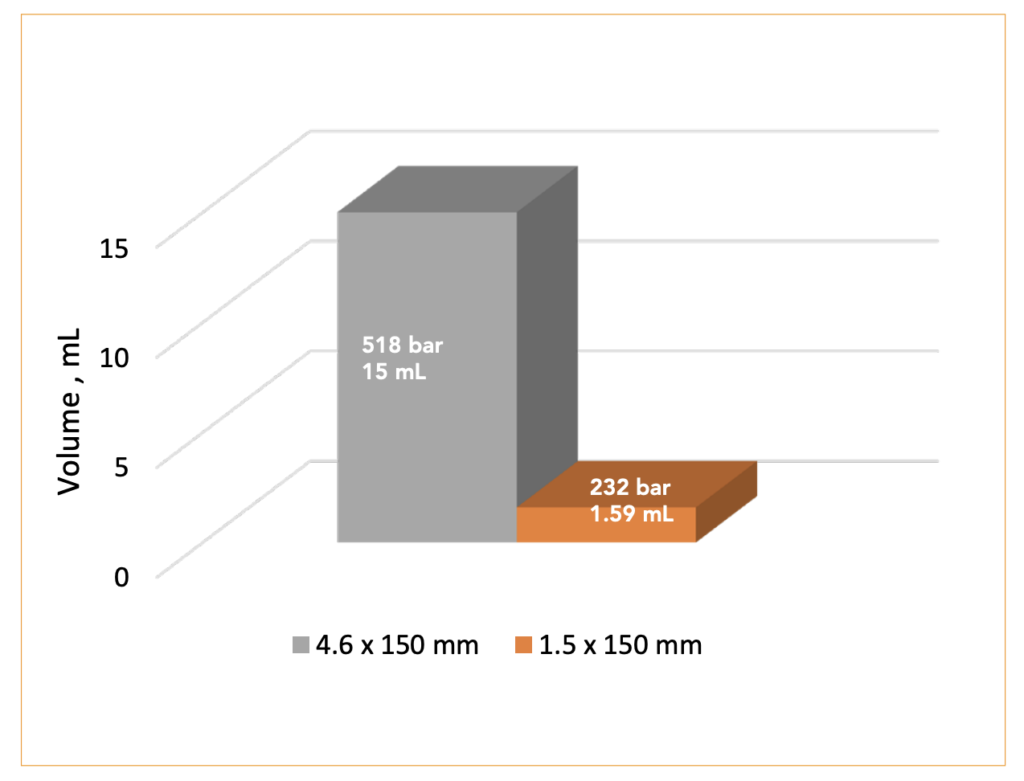

Flow Rate: 0.159 mL/min (1.5 mm); 1.5 mL/min (4.6 mm)

Back Pressure: 232 bar (1.5 mm); 518 bar (4.6 mm)

Temperature: 30 °C

Detection: UV 228 nm, PDA

Injection Volume: 0.5 µL

Sample Solvent: 75/25 ACN/ Water

RESULTS (ALKYLPHENONES):

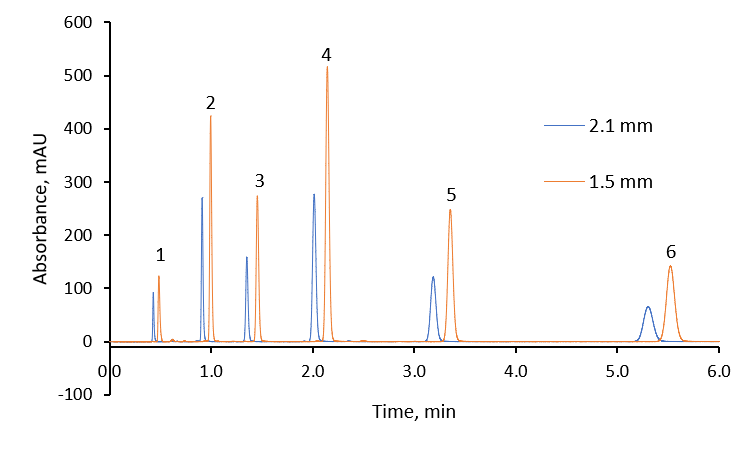

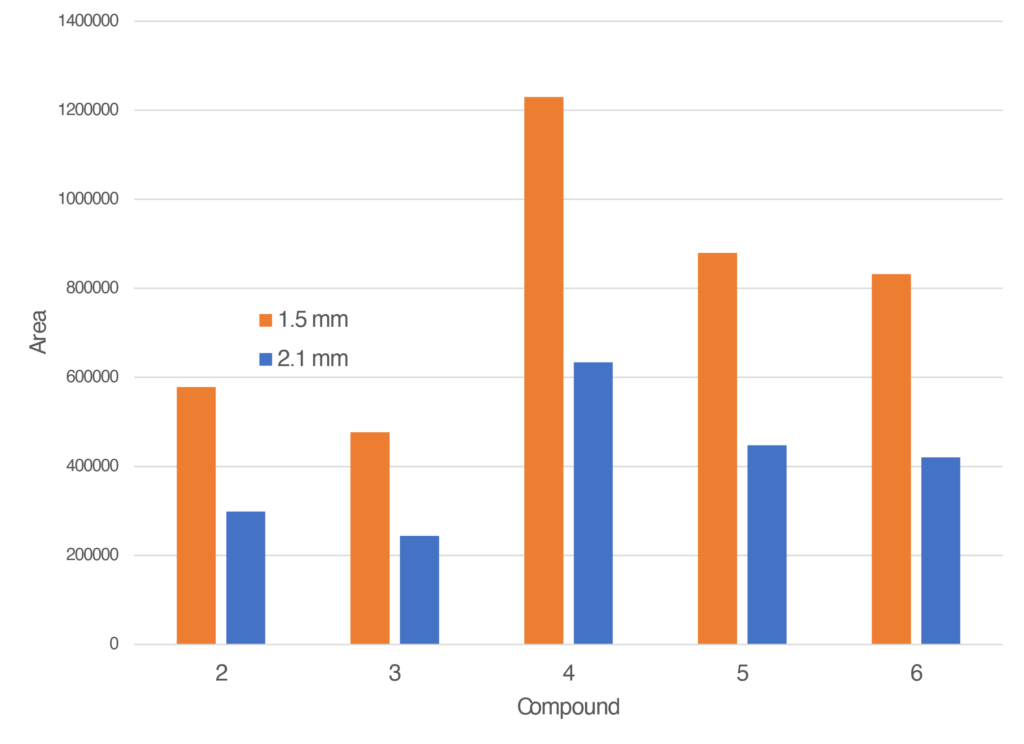

In order to investigate the impact of column ID on the area obtained, a series of alkylphenones was run under isocratic conditions using 1.5 mm and 2.1 mm ID HALO 90 Å C18 columns. The comparison of the two columns is shown in Figure 1.

Figure 1. Isocratic separation of alkylphenones comparing 2.1 mm to 1.5 mm ID. Peak identities (in order) are uracil, acetophenone, propiophenone, butyrophenone, valerophenone, and hexanophenone.

The areas obtained using the 1.5 mm ID column are double those using the 2.1 mm ID column. The same injection volume was used for both columns, which demonstrates that a small volume injected on the 1.5 mm ID results in a taller peak. See Figure 2.

Figure 2. Graph showing an increase of two times the areas with the 1.5 mm ID HALO® column compared to the 2.1 mm ID column. Peak identities same as Figure 1.

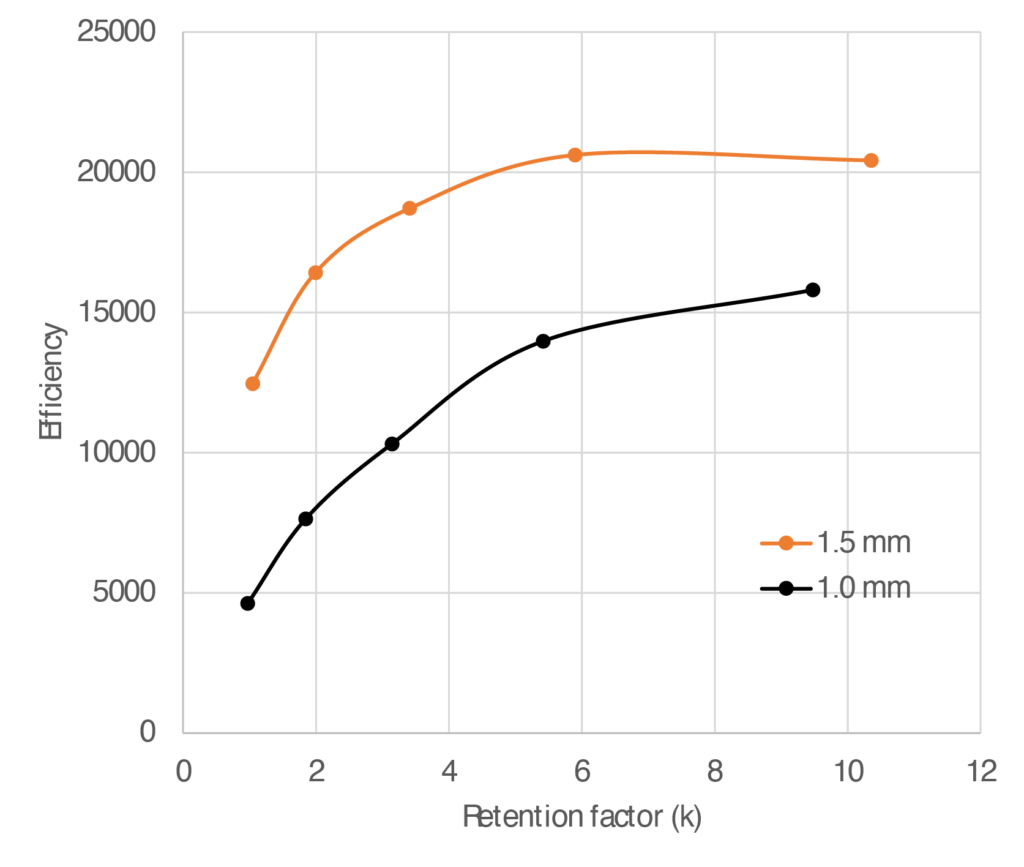

The same separation was run on a 1.0 mm ID HALO 90 Å C18 column. However, the plates were lower compared to the 1.5 mm ID column at every retention factor value, but significantly lower at retention factors less than 4. See Figure 3.

Figure 3. Effect of retention factor on efficiency using 1.5 mm and 1.0 mm HALO 90 Å C18 columns.

As previously mentioned the impact of extracolumn dispersion is increased as the column ID is decreased. The 1.0 mm ID column is more susceptible to the impact of extracolumn dispersion thus explaining the cause of the reduced efficiency. In order to observe the true performance of the 1.0 mm ID column, a lower dispersion HPLC system would need to be used.

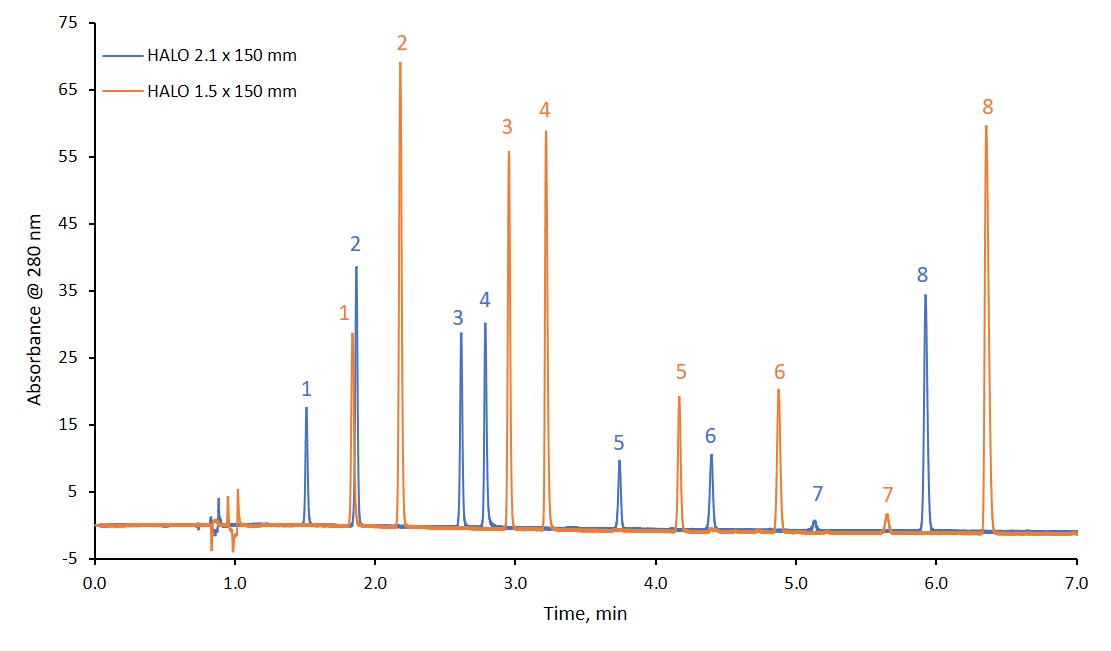

RESULTS (COUGH AND COLD MEDICINES):

A gradient separation of common over-the-counter cough and cold medicines was run to further demonstrate the advantages of using a 1.5 mm ID HALO 90 Å C18 column over a 2.1 mm ID HALO 90 Å C18 column. Analysis of these compounds is commonly performed. Note the sensitivity improvement aids separations where minor components are present, such as for salicylic acid (peak 7), which is a decomposition product of aspirin (peak 6).

Figure 4. Comparison of a gradient separation of common over-the-counter cough and cold medicines run on 1.5 mm and 2.1 mm columns. Peak identities (in order) are phenylephrine, acetaminophen, caffeine, doxylamine, guaifenesin, aspirin, salicylic acid, and dextromethorphan.

Similar to the isocratic separation of alkylphenones, the peak areas for the cough and cold medicines were doubled with the 1.5 mm ID column compared to the 2.1 mm ID column along with two times the savings in solvent consumption.

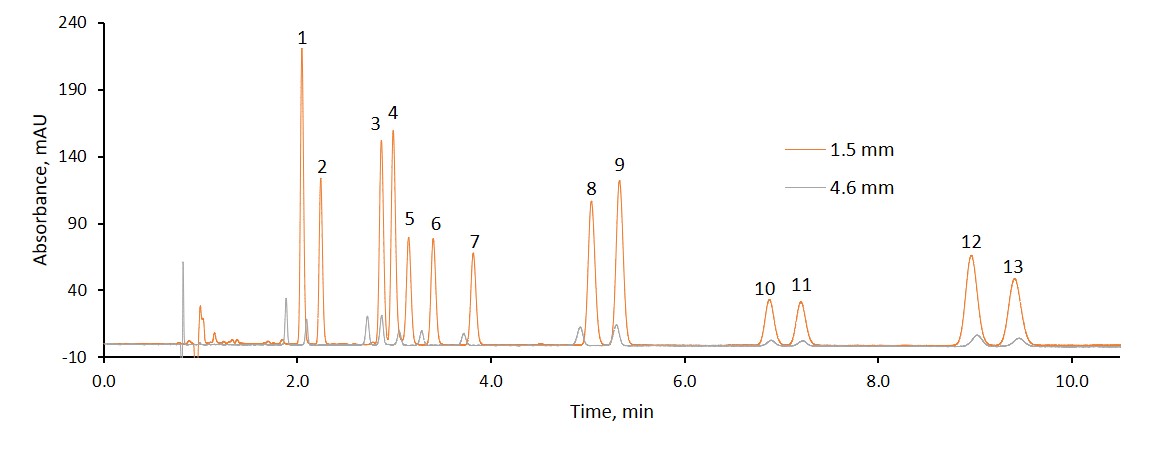

RESULTS (CANNABINOIDS):

In order to demonstrate the impact of sensitivity and solvent savings, a 1.5 mm ID HALO 90 Å C18 column was run compared to a 4.6 mm ID HALO 90 Å C18 column using a mixture of 13 cannabinoids. The flow rate was scaled on the 1.5 mm ID column so that the same linear velocity was used for both columns. The separation is shown in Figure 5.

By reducing the column ID from a 4.6 mm ID to a 1.5 mm ID, the solvent consumption is reduced from 15 mL/ injection to 1.59 mL/injection, which is a reduction of 9.4 times. See Figure 6.

Figure 6. Comparison of the solvent used per injection for a 4.6 mm ID compared to a 1.5 mm ID column.

CONCLUSION:

The new HALO® 1.5 mm ID columns offer a reliable microflow column solution that enables increased sensitivity, reduced solvent consumption/waste disposal, and reduced sample consumption for a variety of applications.

Bridging a gap between a 2.1 mm ID and a 1 mm ID with the ability to be used on standard UHPLC systems provides a balance of ease of use from an analytical system with implementation to that of standard analytical columns and the increased sensitivity provided by a specialized microflow system. The robust column design, manufactured in Advanced Materials Technology’s ISO-accredited facility provides quality assurance measures resulting in long column lifetimes and excellent reproducibility.

REFERENCES:

- J. P. Grinias, B. Bunner, M. Gilar and J. W. Jorgenson, Chromatography, 2(4), (2015) 669-690.

- D.R. Stoll, K. Broeckhoven, LCGC North America. 39, Issue 4 (2021) 159–166.

- G. Desmet, K. Broeckhoven, TrAC Trends Anal. Chem. 119 (2019) 115619.

- K. Broeckhoven, J. De Vos, and G. Desmet, LCGC Europe 30 (2017) 618– 625.